The Perils of Concrete: A Cautionary Tale

Ah, concrete – that ubiquitous material that shapes our modern world, from towering skyscrapers to humble sidewalks. It’s the unsung hero of the construction industry, quietly supporting our daily lives. But, my friends, beware! For beneath the smooth, solid surface of concrete lies a minefield of potential pitfalls, ready to trip up the unwary.

As the owner of a concrete finishing company in the bustling city of Nashville, I’ve seen it all. From the freshly poured slab that turned into a cracked, uneven mess to the beautifully stamped patio that faded faster than a Nashville summer sun. Believe me, I know the pain of watching your hard work slowly turn to rubble before your eyes.

But fear not! In this article, I’m going to share with you the hard-won wisdom I’ve gathered over the years, like a treasure trove of concrete-related cautionary tales. So, grab a cup of coffee (or a cool glass of Tennessee whiskey, if that’s more your style), and let’s dive into the world of concrete finishing, where every step must be taken with the utmost care and attention.

The Curse of Improper Curing

Ah, the curing process – the unsung hero of concrete finishing. It’s like a delicate dance, where you must carefully control the temperature, humidity, and time to ensure your concrete reaches its full strength and durability. But, oh, the pitfalls that await the unwary!

Imagine, if you will, a freshly poured slab of concrete, glistening in the sun. The eager homeowner can’t wait to put their fancy new patio furniture on display. But, alas, they’ve jumped the gun. You see, concrete needs time to properly cure, to develop that rock-solid strength that will withstand the test of time.

Rushed curing can lead to all sorts of problems – from surface crazing and cracking to premature deterioration and even structural failure. It’s like trying to run a marathon without warming up first; the results are never pretty.

I once had a client who was so eager to show off their new driveway that they skipped the curing process altogether. Within a year, the poor thing was a pockmarked, crumbling mess. It was a heartbreaking sight, like watching a beloved pet slowly wither away. Needless to say, they were not pleased, and I spent many an hour trying to explain the importance of proper curing.

But, fear not, my friends! With a little patience and attention to detail, you can avoid this pitfall. Follow the manufacturer’s instructions to the letter, and be prepared to adjust your curing methods based on the weather conditions. Trust me, your concrete will thank you for it, and your clients will be singing your praises for years to come.

The Scourge of Improper Finishing

Ah, the finishing touch – the moment when you transform a mere slab of concrete into a work of art. But, oh, the horrors that can unfold if you don’t have a deft hand and a keen eye!

Imagine, if you will, a beautifully stamped patio, its intricate patterns casting shadows that dance across the surface. But, alas, the homeowner notices that the colors are fading, and the once-sharp edges have become dull and rounded. It’s like watching a masterpiece slowly crumble before your eyes.

You see, concrete finishing is a delicate art, requiring a careful balance of techniques and materials. From the selection of the right color hardener to the precise timing of the stamping process, every step must be executed with the utmost care and precision.

I once had a client who insisted on using a cheaper, off-the-shelf sealant for their brand-new concrete driveway. Within a matter of months, the surface had turned an unsightly, mottled gray, and the once-vibrant colors had faded to a dull, lifeless hue. It was a painful sight, like watching a sunset fade to black.

But fear not, my friends! With the right techniques and the proper materials, you can create concrete finishes that will stand the test of time. From carefully selecting the right color additives to meticulously applying the sealant, every step is crucial. And, of course, don’t forget the all-important curing process – the foundation upon which all great concrete finishes are built.

Remember, concrete finishing is an art, not a science. It takes practice, attention to detail, and a deep understanding of the materials and techniques involved. But, trust me, the end result is worth it – a stunning, durable surface that will be the envy of all your neighbors.

The Perils of Poor Surface Preparation

Ah, the humble concrete surface – the foundation upon which all great projects are built. But, my friends, beware! For if this crucial first step is not executed with the utmost care and attention, the rest of your project is doomed to failure.

Imagine, if you will, a freshly poured concrete slab, gleaming in the sun. The homeowner is ready to transform it into a masterpiece – a beautifully stamped patio, or perhaps a sleek, polished floor. But, alas, the surface is not properly prepared, and the end result is a disaster.

I once had a client who insisted on skipping the surface preparation step, convinced that they could save a few bucks in the process. But, oh, the price they paid! Within a matter of months, the beautiful stamped patio they had envisioned had turned into a cracked, uneven mess, like a jigsaw puzzle gone horribly wrong.

You see, proper surface preparation is the key to ensuring that your concrete finishes stand the test of time. From grinding and cleaning the surface to ensuring the proper pH levels, every step must be executed with the utmost care and attention.

Imagine a house of cards, with each layer precariously balanced on the one below it. If the foundation is not solid, the entire structure is doomed to collapse. The same principle applies to concrete finishing – without a proper foundation, your project is destined to fail.

But fear not, my friends! With the right techniques and a keen eye for detail, you can ensure that your concrete surfaces are primed and ready for the finishing touches. From thorough cleaning to meticulous grinding and profiling, every step is crucial. And, of course, don’t forget to test the surface for any potential issues, like excessive moisture or pH imbalances.

Remember, the key to successful concrete finishing is to never underestimate the importance of surface preparation. It may not be the most glamorous part of the job, but it’s the foundation upon which all great projects are built. So, take the time, do it right, and reap the rewards of a smooth, durable surface that will stand the test of time.

Avoiding the Scourge of Improper Expansion Joints

Ah, the oft-overlooked expansion joint – the unsung hero of the concrete world. These humble gaps in the surface may seem like mere trifles, but trust me, my friends, they hold the power to make or break your concrete project.

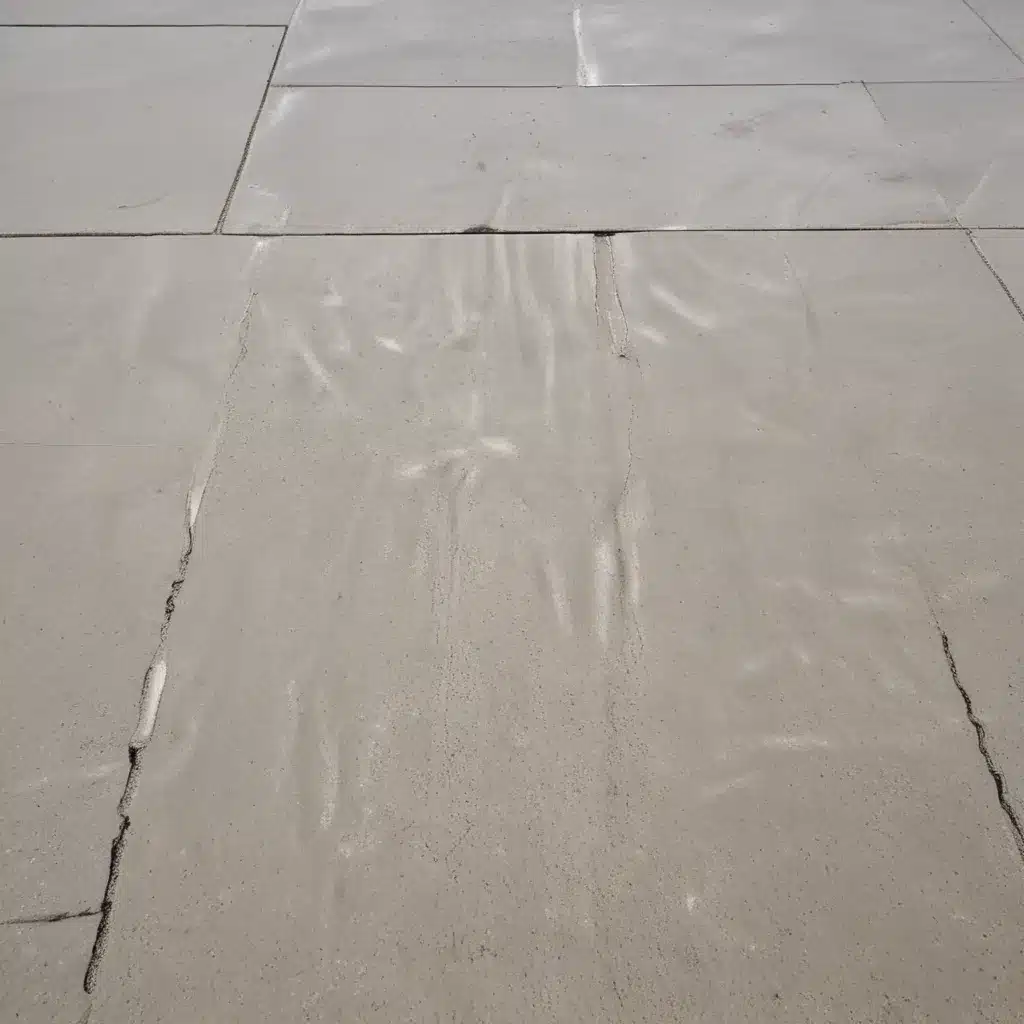

Imagine, if you will, a sleek, polished concrete floor, gleaming like a mirror. The homeowner is thrilled, already envisioning their new modern furniture adorning the space. But, alas, the expansion joints have been neglected, and the entire floor is a spiderweb of cracks, like a shattered windshield.

You see, concrete, for all its strength and durability, is a living, breathing material. It expands and contracts with changes in temperature and moisture, and if those movements are not properly accommodated, the results can be disastrous.

I once had a client who insisted on skipping the expansion joints altogether, convinced that they would ruin the aesthetic of their new patio. But, oh, the price they paid! Within a matter of months, the entire surface was a patchwork of cracks, like a twisted, deformed work of modern art.

Imagine a bridge without expansion joints – it would be like trying to hold back the tides with a sandcastle. The constant stress and strain would eventually tear the structure apart, piece by piece.

But fear not, my friends! With a little planning and attention to detail, you can avoid the scourge of improper expansion joints. From carefully calculating the size and placement of the joints to ensuring they are properly sealed and maintained, every step is crucial.

Remember, concrete may be a sturdy material, but it’s not invincible. It needs room to move and breathe, and the expansion joint is the key to allowing it to do just that. So, take the time, do it right, and you’ll be rewarded with a smooth, crack-free surface that will stand the test of time.

The Curse of Improper Concrete Curing Compounds

Ah, the humble curing compound – the unsung hero of the concrete world. These seemingly innocuous liquids hold the power to make or break your concrete project, like a genie in a bottle, waiting to be unleashed.

Imagine, if you will, a freshly poured concrete slab, glistening in the sun. The homeowner is eager to see their new patio take shape, already envisioning backyard barbecues and lazy summer afternoons. But, alas, the wrong curing compound has been used, and the entire surface is a dull, lifeless hue, like a bad case of concrete acne.

You see, the curing compound is the key to ensuring that your concrete develops the proper strength and durability. It’s like a protective shield, shielding the delicate surface from the harsh elements and allowing the concrete to reach its full potential.

I once had a client who insisted on using a budget-friendly curing compound, convinced that they could save a few bucks in the process. But, oh, the price they paid! Within a matter of months, the beautiful, glossy finish they had envisioned had turned into a dull, mottled mess, like a bad case of concrete sunburn.

Imagine a plant without water – it would wither and die, its once-vibrant leaves turning brown and brittle. The same principle applies to concrete; without the proper curing, it will never reach its full potential.

But fear not, my friends! With a little research and attention to detail, you can avoid the curse of improper curing compounds. From carefully selecting the right product for your specific project to ensuring proper application, every step is crucial.

Remember, the curing compound is the unsung hero of the concrete world, quietly working behind the scenes to ensure your project’s success. So, take the time, do it right, and you’ll be rewarded with a beautiful, durable surface that will stand the test of time.

Navigating the Treacherous Waters of Concrete Color Selection

Ah, the world of concrete color selection – a veritable minefield of potential pitfalls, where the wrong choice can turn your dream project into a nightmare.

Imagine, if you will, a beautifully stamped patio, its intricate patterns and vibrant hues bringing a touch of magic to the backyard. But, alas, the homeowner has chosen a color that clashes horribly with the surrounding landscaping, like a fashion faux pas on a grand scale.

You see, concrete color selection is a delicate balancing act, where every factor must be carefully weighed and considered. From the project’s overall aesthetic to the surrounding environment, the wrong choice can spell disaster.

I once had a client who insisted on a bold, vibrant red for their new driveway, convinced that it would make a statement. But, oh, the horror that unfolded! The intense color clashed with the neutral tones of the nearby houses, making the entire space look like a garish, overly-bright carnival.

Imagine a painter’s palette, with every color carefully curated to create a masterpiece. The same principle applies to concrete color selection – every hue must be chosen with the utmost care and attention.

But fear not, my friends! With a little guidance and a keen eye for design, you can navigate the treacherous waters of concrete color selection with ease. From carefully considering the surrounding environment to exploring a range of complementary shades, every step is crucial.

Remember, the color of your concrete is not just a matter of personal preference – it’s a crucial element in the overall aesthetic of your project. So, take the time, do your research, and you’ll be rewarded with a stunning, cohesive space that will be the envy of all your neighbors.

The Perils of Improper Concrete Sealant Application

Ah, the concrete sealant – the unsung hero of the finishing process, quietly protecting your investment from the ravages of time and the elements. But, my friends, beware! For if this crucial step is not executed with the utmost care and attention, the results can be disastrous.

Imagine, if you will, a beautifully stamped patio, its intricate patterns and vibrant hues capturing the essence of your outdoor oasis. But, alas, the sealant has been applied with a heavy hand, leaving behind an unsightly, uneven sheen, like a bad case of concrete sunburn.

You see, the sealant is the final layer of defense, protecting your concrete from the elements and ensuring its long-term durability. But, like any powerful tool, it must be wielded with precision and care.

I once had a client who insisted on applying the sealant themselves, convinced that they could save a few bucks in the process. But, oh, the price they paid! Within a matter of months, the once-stunning patio had turned into a dull, lifeless mess, with the sealant peeling and flaking off like a bad case of dandruff.

Imagine a precious work of art, encased in a thick, uneven layer of glass – the beauty and detail would be lost, obscured by the heavy-handed application. The same principle applies to concrete sealant – too much, and you risk ruining the entire project.

But fear not, my friends! With the right techniques and a keen eye for detail, you can ensure that your concrete sealant application is nothing short of perfection. From carefully preparing the surface to meticulously applying the sealant in thin, even coats, every step is crucial.

Remember, the sealant is the final layer of protection, the last line of defense against the ravages of time and the elements. So, take the time, do it right, and you’ll be rewarded with a stunning, durable surface that will be the envy of all your neighbors.

The Curse of Improper Concrete Mixing

Ah, the humble act of concrete mixing – a seemingly simple task, yet one fraught with peril, like a minefield of potential pitfalls just waiting to be triggered.

Imagine, if you will, a freshly poured concrete slab, its smooth, even surface a testament to the skill and expertise of the crew. But, alas, the homeowner soon notices cracks and crumbling, like a bad case of concrete acne.

You see, the secret to successful concrete lies in the perfect balance of ingredients – the right amount of cement, aggregate, water, and admixtures, all mixed with the precision of a master chef. Stray even slightly from the recipe, and the results can be disastrous.

I once had a client who insisted on skimping on the cement, convinced that they could save a few bucks in the process. But, oh, the price they paid! Within a matter of months, the entire slab had turned into a crumbling, uneven mess, like a badly baked cake.

Imagine a building without a solid foundation – it would be like trying to stand a house of cards in the middle of a hurricane. The same principle applies to concrete; without the proper mix, the entire structure is doomed to failure.

But fear not, my friends! With a keen eye for detail and a deep understanding of the science behind concrete mixing, you can avoid the curse of improper concrete mixing. From carefully measuring and blending the ingredients to ensuring proper curing and finishing, every step is crucial.

Remember, concrete may seem like a simple material, but it’s a delicate balance of art and science. So, take the time, do it right, and you’ll be rewarded with a durable, long-lasting surface that will stand the test of time.

Navigating the Treacherous Waters of Concrete Contraction Joints

Ah, the humble contraction joint – the unsung hero of the concrete world, quietly working behind the scenes to ensure the longevity and stability of your project. But, my friends, beware! For if this crucial element is not properly installed, the consequences can be dire.

Imagine, if you will, a beautifully finished concrete slab, its smooth surface a testament to the skill and expertise of the crew. But, alas, the homeowner soon notices a web of cracks, like a shattered windshield, spreading across the surface.

You see, concrete, for all its strength and durability, is a living, breathing material, constantly expanding and contracting in response to changes in temperature and moisture. And without the proper contraction joints to accommodate these movements, the result can be a structural nightmare.

I once had a client who insisted on skipping the contraction joints altogether, convinced that they would ruin the aesthetic of their new patio. But, oh, the price they paid! Within a matter of months, the entire surface was a patchwork of cracks, like a twisted, deformed work of modern art.

Imagine a bridge without expansion joints – it would be like trying to hold back the tides with a sandcastle. The constant stress and strain would eventually tear the structure apart, piece by piece.

But fear not, my friends! With a little planning and attention to detail, you can navigate the treacherous waters of concrete contraction joints with ease. From carefully calculating the size and placement of the joints to ensuring proper installation and sealing, every step is crucial.

Remember, concrete may be a sturdy material, but it’s not invincible. It needs room to move and breathe, and the contraction joint is the key